Description

一、Structural Stability to Ensure Safe Operation

-

Electrical brackets typically use high-strength materials (such as stainless steel, aluminum alloy, or engineering plastics), combined with welding and bolt fastening processes. This firmly fixes fish aggregating lamps to the ship's side, mast, or other positions, preventing the lamps from falling off or being damaged

-

The load-bearing capacity of the bracket is customized according to the weight and specifications of the fish aggregating lamps, ensuring balance when multiple lamps are installed simultaneously. This avoids affecting the stability of the fishing vessel due to center of gravity deviation (especially suitable for the layout of large fish lamp sets).

-

Due to the strong corrosiveness of salt spray in marine environments, the bracket surface is often galvanized, sprayed with anti-rust paint, or anodized to extend service life and reduce the risk of structural looseness caused by corrosion

二、Flexibility for Diverse Operational Needs

- Some brackets feature rotating joints, telescopic rods, or foldable structures, allowing adjustment of the irradiation angle (e.g., 俯角 [depression angle], horizontal direction) and hanging height of the fish aggregating lamps based on fish school depth and lighting range requirements.

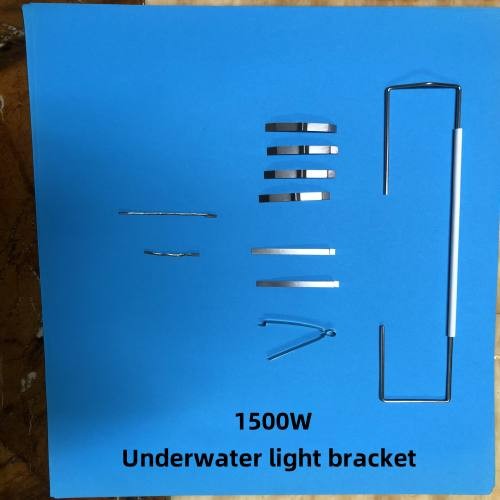

- Universal brackets can accommodate fish aggregating lamps of different powers and sizes (such as LED lamps, halogen lamps). By replacing fixing accessories or adjusting installation holes, they enable quick adaptation during equipment upgrades, reducing renovation cost

- Brackets can be designed as multi-lamp parallel structures (such as beam-type or matrix-type), supporting the simultaneous installation of multiple fish aggregating lamps to form a three-dimensional lighting network. This eliminates the lighting blind spots of single lamps and improves fish attraction efficiency